The Rubber Component Experts

The Rubber Component Experts

Click on a list below for more details…

The term Rubber Mouldings covers a wide range of rubber types, each possessing material characteristics suited to specific applications. We are able to provide expert advice on the use of the right material for your own rubber component applications, but the following list provides a simple reference for the main rubber types and their properties.

The summary lists the key advantages of each material, but care must be taken to ensure the overall properties of the rubber before final selection.

Contact us for a full technical specification and advice on material selection.

Rubber mouldings materials and their key properties:

Silicone Rubber (Chemical Designation: Polysiloxane)

a temperature resistant material ideal for many aerospace, automotive, appliance and electrical requirements. It is also a significantly more costly option.

Nitrile (NBR) Rubber (Chemical Designation: Butadiene Acrylonitrile (NBR))

resistant to petroleum oils and aromatic hydrocarbons, NBR has high resistance to mineral and vegetable oils and acids with good elongation, resilience, tensile and compression properties.

Viton® Rubber (Chemical Designation: Fluorinated Hydrocarbon)

a new member of the Fluorelastomer class, Viton® is resistant to a wide variety of corrosive fluids at elevated temperatures with good tensile strength, resilience and low compression.

Neoprene Rubber (Chemical Designation: Chloroprene (CR)

an all-purpose elastomer, resistant to ozone, sunlight, oxidation and many petroleum with the added advantage of good resistance to water and many chemicals with good resilience and tensile strength.

Natural Rubber (Chemical Designation: Natural Polyisoprene (NR))

Key advantages of high resilience, good tensile strength, tear resistance and notable wear resistance, with low permanent set characteristics and good flexing qualities at low temperatures.

EPDM Rubber (Chemical Designation: Ethylene Propylene (EPR & EP))

ideal for outdoor applications, resistant to ozone, oxidants, and severe weather. Excellent colour stability, heat resistance, and dielectric qualities. Offers the advantages of neoprene, at a lower cost.

SBR Rubber (Chemical Designation: Styrene Butadiene, Buna S, GRS)

provides very fine abrasion, wear, and tensile qualities and can be a lower cost substitute for natural rubber in many applications. SBR has essential properties about the same as Natural Rubber.

Polyurethane (Chemical Designation: Polyester or Polyether Urethane)

good elongation and high tensile strength, with excellent abrasion and tear strength and good resistance to ozone and oxygen. Polyurethane has low coefficient of friction.

Fluorosilicone (Chemical Designation: Fluoro-Vinyl Silane)

ready adaptable for use with electricity, temperature extremes and a wide range of chemicals, Fluorosilicone has a high resistance to flame, weather, oxidation, ozone, silicate hydraulic fluids, alkalis, alcohol and synthetic lubricants.

Hypalon® (Chemical Designation: Chlorosulfonated Polyethylene)

outstanding resistance to most chemicals, heat and oil; flame resistant, excellent colour stability, weather and abrasion resistance. Low moisture absorption, good dielectric qualities, and high abrasion resistance.

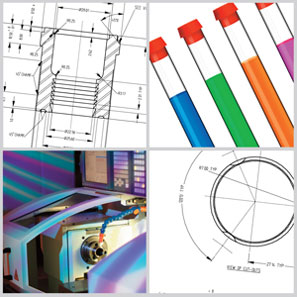

Fairham Mouldings provide a complete in-house design and manufacturing solution for precision rubber mouldings, with facilities available to meet the most demanding client specifications.

Our comprehensive in-house facilities include:

Tool Room

Supported by associated tooling facilities including cutting and welding equipment.

1 x 360 tonne mould press, capacity 36”x 52”

11 x mould presses, 15 to 100 tonnes, capacity 15”

Supported by associated finishing facilities

Our key sectors include: